03/11/2016

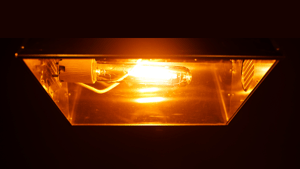

Lighting Comparison: LED vs High Pressure Sodium/Low Pressure Sodium

LED Retrofit,

Wall Pack Lighting,

Parking Garage Lighting,

LED Lighting,

Retail Lighting,

Commercial Lighting,

Parking Lot Lighting,

Lighting Education,

Outdoor Lighting,

Stouch Lighting Services,

Lighting Comparison