Industrial Lighting

What is Industrial Lighting?

Industrial Lighting applies to a range of unique tasks and environments including food and beverage facilities, warehouse and distribution centers, manufacturing facilities, transportation and terminals, and energy, waste, and chemical plants. Industrial spaces require highly customized lighting solutions to provide a safe and productive work environment. The right lighting can improve work and safety conditions, while also increasing efficiency, improving light performance, and saving big on energy costs.

Consider Your Space

Consider Your Space

Industrial spaces are great candidates for energy efficient solutions because they usually require optimal illumination in large spaces and operate for long hours (sometimes 24 hours). Industrial spaces also have unique safety standards and lighting requirements that we discuss in more detail below.

When choosing lighting for Industrial spaces, it's important to consider the tasks that need to be performed, the building regulations that affect overall lighting design, and the location of lights and fixtures, particularly in areas that may be difficult to access for replace and repair. Whether you're choosing interior or exterior lighting, it's vital to take into account: level of illumination, glare, color & mood (for productivity), energy usage, lighting standards and safety requirements, and any special requirements specific to your facility or space

High Bay & Low Bay Lighting

High bay and low bay lights are popular in large indoor spaces like factories and distribution facilities, with open space and high ceilings. They are typically mounted via a pendant or chain, or directly to a ceiling or ceiling girder.

Industrial spaces require appropriate light levels on the ground and at work stations for employee visibility.

Maintenance is an important factor to consider when choosing high bay lighting, as these fixtures and bulbs are more difficult to replace given their location and access limitations. That's why many industrial spaces rely on industrial high bay LED lights.

Strip Fixtures

Strip light fixtures are for indoor and outdoor illumination and can be mounted directly to the ceiling or suspended in a variety of ways for general and consistent illumination on the ground. Strip fixtures are versatile and can be used in many spaces.

Industrial LED strip lights are often direct replacements for old fluorescent strip lighting. Industrial LED strip lights are used to distribute powerful, uniform light in large areas where light needs to be dispersed. Smaller industrial led strip lights can also be used to illuminate tight or unique spaces.

Vapor Tight Lighting

Vapor tight fixtures are sealed and gasketed luminaires that provide lighting for environments exposed to water, humidity, and dust is likely to occur.

Commonly referred to as “wet location” fixtures, vapor tight lights comes in a variety of sizes and shapes, but most commonly found in 2ft, 4ft, and 8ft lengths. They are usually mounted on ceilings, soffits, walls, or in any other building or facility where exposure to water or dust is a concern.

Vapor tight may be a type of hazardous location lighting, which we delve into further below.

Troffers & Office Lighting

Troffer lighting (aka recessed troffer lighting) is a term that is often used to describe indoor lighting fixtures that are mounted within a ceiling grid, hence the term “recessed.”

Typical fixture sizes include 1x4 troffers, 2x2 troffers, and 2x4 troffers. This type of interior lighting is located in a range of building types and workplace usage, and is commonly used to provide illumination for industrial and warehouse applications.

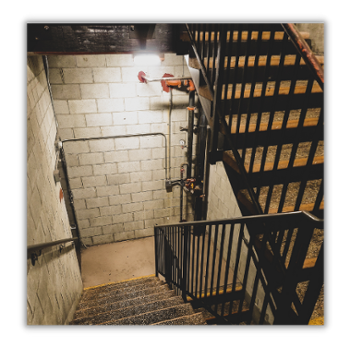

Stairwell/Corridor

Stairwell lighting is just as it sounds - lights and fixtures used to illuminate your stairwells and corridors to keep employees and visitors (as applicable) safe. According to OSHA, most workplace injuries happen in stairwells, so it's extremely important to keep your stairwells, corridors, and catwalks well-lit.

Stairwells usually require constant illumination, but switching to LEDs and utilizing sensors (so the lights only turn on when the spaces are occupied) saves big money.

Task Lighting

Task lighting and work lamps are important for industrial settings where detailed tasks, like packaging, food prep, chemical work, parts assembly etc, are required. Task lighting is vital to ensure accuracy of tasks, and it adds to general illumination.

LED task lights with industrial lighting fixtures can provide directional lighting, ensuring the necessary area is illuminated for maximum safety, efficiency, and productivity. Many LED fixtures also have adjustable arms and can be installed at each workspace to give custom lighting to each employee.

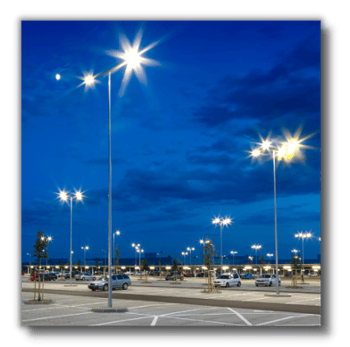

Parking and Area Lighting

Parking lot lights are those pole mounted fixtures used to illuminate parking areas at your facility. LED lighting is ideal for lots used by customers or employees that leave their vehicles for several hours. Remember, it's vital to have effective parking lot lights to keep employees safe, especially in many industrial sectors, where employees could be walking to their cars after a second or third shift.

High Mast Lighting

High mast lighting is a type of outdoor site light fixture that is commonly used to illuminate large areas from a very high mounting height. You might see this type of lighting application at transportation terminals, correctional facilities, sports venues, and energy, waste, and chemical plants.

For industrial applications, high mast lights would be useful for shipping depots, where large trucks are stored and/or loaded with products and goods, as an example. They're also used instead of, or as parking lot lights, when conventional, lower to the ground parking lot lighting doesn't suffice because the lot is so large and requires that additional illumination.

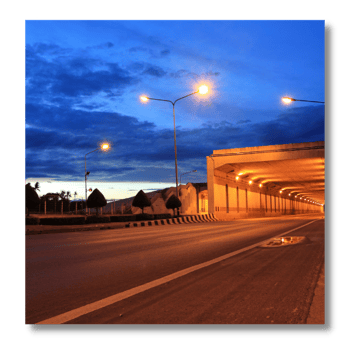

Roadway Lighting

Industrial roadway and tunnel lighting is commonly found on physical plant or campus pathways, tunnels, bridges, loading docks, etc. These are frequently pole mounted or tunnel light fixtures that require significant resistance to vibration and hazardous locations that provide even illumination on the ground, whether for cars, trains, trucks, or other transport. LED tunnel lights and road lights provide better lighting performance and efficiency! If you have a roadway lighting project coming up, consider LEDs for their lighting performance and efficiency.

Wall Pack Lighting

Wall Pack and Building Lighting are outdoor lighting fixtures commonly mounted on the exterior walls of buildings. Industrial outdoor wall lights are generally used to provide illumination to areas for vehicles and pedestrian use, as well as for security purposes. It is not uncommon to see multiple fixtures mounted on a single building or wall, with the fixture spacing designed to provide lighting at the ground level around the exterior of a building. These lights make the outside of your building safe and visible.

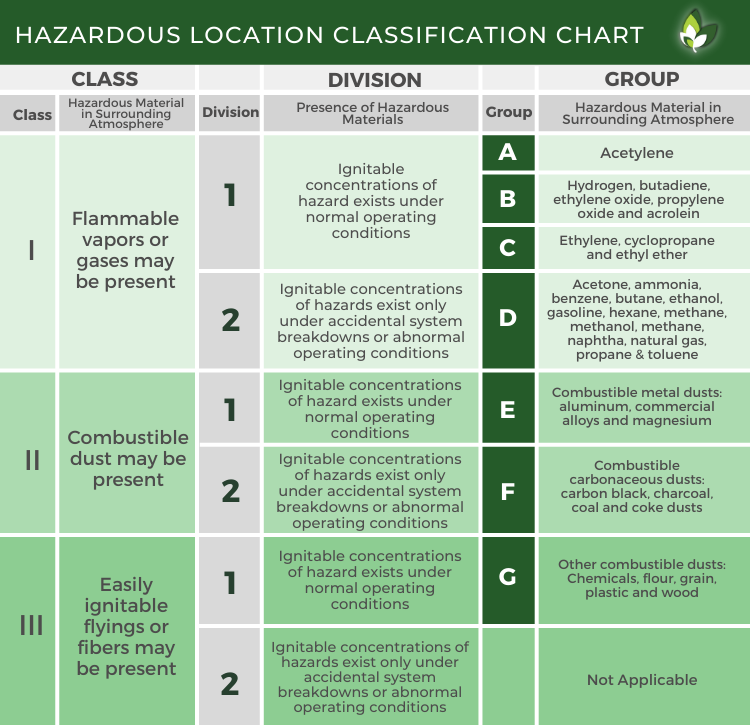

Hazardous classified locations are areas within a facility or property where the possibility of explosion or fire hazards may exist under abnormal or normal conditions, due to the presence of combustible, flammable, or ignitable liquids, vapors, gases, dust or fibers.

The hazardous location classification system is defined by the National Fire Protection Association (NFPA) 70®, National Electric Code® (NEC). NFPA 70 NEC Articles 500 through 503 cover the requirements for electrical/electronic equipment and wiring for all voltages in Class I, Divisions 1 and 2; Class II, Divisions 1 and 2; and Class III, Divisions 1 and 2 locations.

OSHA (Occupational Safety and Health Administration) has adopted the hazardous classifications and requires that all equipment used in hazardous locations be marked with the class, group, and operating temperature range for which it is approved.

Classes

- Classes define the type of ignitable or explosive substances that may be present in the surrounding atmosphere.

- Class I - Flammable gases and vapors may be present, such as natural gas, petroleum, & chemical.

- Class II - Combustible dust may be present, such as dust from the pulverizing process. Combustible dusts can also be found inside plastics, pharmaceutical, coal, and grain and flour processing facilities.

- Class III - Easily ignitable flyings or fibers may be present. Common industries here include wood, cotton, and textile industries.

Division

- Divisions define the likelihood of the hazardous material being present in an explosive or ignitable concentration.

- Division 1 - ignitable gas, dust, or vapors are present during normal operating conditions

- Division 2 - ignitable gas, dust, or vapors only found during abnormal conditions

Groups

- Group(s) are defined by the specific hazardous materials that may be present. Group descriptions are in the chart below.

Explore the Hazardous Location Classification Chart Below:

Download a PDF Version of the Chart Above

Industrial Lighting Standards & Safety Requirements

In industrial applications, lighting often must comply with certain safety and sanitation standards. But understanding the different certifying bodies and certifications light fixtures can achieve is confusing.

We've defined some of the public health organizations (both federal and private) responsible for regulating lighting as well as their specific certifications for these products:

Note that these won't all be relevant for every industrial application:

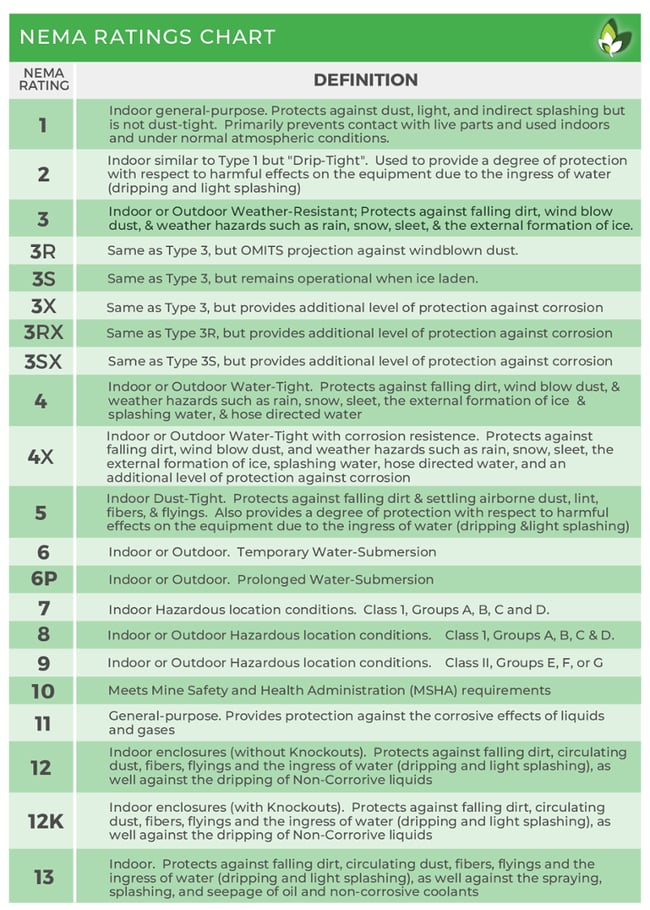

NEMA Enclosure Rating

The National Electrical Manufacturers Association (NEMA) provides a rating system for classifying heavy duty electrical enclosures used in industrial, Commercial, and Municipal lighting applications. The NEMA rating indicates to what degree an enclosure is protected against a variety of environmental hazards (such as water, gas, oil, and dust, etc.).

Download a PDF Version of the Chart Above

Ingress Protection Ratings (IP Ratings)

The Ingress Protection rating system is classification developed by the IEC that rates and classifies the degree of projection that an electrical enclosure has against the intrusion of water and dust.

Although similar to NEMA Enclosure Ratings, IP Ratings were established by a different governing body and are used worldwide, whereas NEMA ratings are mostly utilized in the US and Canada. Also, while IP Rating system is wider in its geographical adoption, it is limited to measuring the ingress of dust and water, whereas NEMA ratings account for a much broader range of exposure to corrosive and explosive environments.

Download a PDF Version of the IP Rating Chart Above

NSF Certification

NSF International provides a certification system that establishes standards for food protection and sanitation in regards to the design, materials, construction, fabrication, and performance of lighting fixtures. This applies to both the specific lighting product, as well as the facility in which it was manufactured.

-1.png?width=400&name=Industrial%20Lighting%20Pillar%20Page%20Block%20Images%20with%20Shadow%20-%20USED%20May%202021%20(1)-1.png) Vandal-Resistant Lighting

Vandal-Resistant Lighting

Vandal-Resistant lighting is a description of the type of light fixtures that have an increased ability to withstand impacts, prying, tampering, shattering, and severe weather.

Other terms used to describe Vandal-Resistance are Vandal-Proof, Tamper-proof, and High Abuse. What separates Vandal-Resistant lighting fixtures from standard fixtures for the same applications are additional feature such as tamper-proof screws, aluminum or steel housings, and polycarbonate lenses. There is not an independent certifying body that validates vandal resistance, so it is up to the individual product manufacturers to state what features exist on a given product that make it vandal or tamper proof.

Underwriters Laboratories (UL)

UL is a global not-for-profit independent safety analysis company that tests products for safety before they are marketed to businesses or consumers.

UL is one of several OSHA approved organizations approved to perform safety testing in the US. These OSHA approved organizations are all Nationally Recognized Testing Laboratories. While UL is the most common safety “Mark”, there are several other safety testing organizations that provide equivalent safety verification, such as CE, FCC, CSA:

Design Lights Consortium (DLC)

Design Lights Consortium is a non-profit organization that establishes minimum product specifications commonly used by utility companies and other entities that offer rebates to their power customers. There are (3) primary product performance areas in which DLC established compliance requirements:

- CCT (Light Color)

- Distribution (light patterns)

- Product Lifetimes (L70 & TM-21)

DLC provides and maintains a Qualified Products List (QPL) of LED products that have met pre-defined lighting category requirements. These categories include LED Luminaires, linear replacement lamps, and retrofit kits.

Want to take all this info with you? Download this entire page in PDF form

All industries need ways to keep bacteria and other pathogens at bay to protect goods and products, but also to protect employees. All industrial businesses can accomplish both with the right UV-C light fixture in place.

What is germicidal UV light?

Germicidal ultraviolet (UV) light produces shortwave UV-C emissions that disrupt DNA pairing leading to the inactivation of germs. This type of lighting is being used in hospitals, schools, wastewater treatment plants, food processing, and so much more increasingly all the time (learn more about all of its uses here). The UV-C lighting we provide is over 99% effective at killing these pathogens.

Disinfecting Your Air & Surfaces: Using UV Light to Protect Employees

In the midst of the coronavirus pandemic, germicidal UV-C lighting has seen an uptick in popularity because it can inactivate many of the pathogens responsible for viruses and

infections. You can utilize UV-C mobile units or mounted fixtures to kill these kinds of illness-causing pathogens on high touch surfaces and in the air to help keep your employees from getting sick. In an industry that can't shutdown or work from home, this is vital.

Food processing facilities, particularly meat processing, a segment of industrial, are a hotbed for COVID-19, but foods are in high demand as everyone's stocking up for long periods at home. Keep your plant from permanent closure by keeping employees healthy.

UV Lighting for Food & Beverage: A Chemical-Free Irradiation Option

Did you know that UV lighting has been used in food processing for hundreds of years for food irradiation? It kills common food-borne bacteria like E. coli, Salmonella, and Listeria that can cause serious illnesses and even death. UV-C lighting has been tested so it can effectively prevent food contamination and also extend food shelf life. The lighting technology can not only prevent mold, sprouts, insects, etc. from growing and thriving directly on food, it can also treat food packaging and other foodstuff. This includes conveyors and other equipment to transport the food and working surfaces (as discussed above).

Another high growth area for UV-C lighting is specifically for beverages, dairy, and other pasteurized products. UV-C has already been used to sanitize water in municipalities and also bottled water in factories for decades, but it also has potential to replace pasteurization of juices, milk, and more. Pasteurization is known to kill the good along with the bad, lessening vitamin and mineral levels in important products. UV-C light would eliminate this issue as it does not change the chemical makeup of foods and beverages it treats.

Moreover, as chemical disinfectants, preservatives, and other irradiation methods for food come under increased scrutiny and more and more are banned (citing claims of cancer and birth defects), irradiation options like UV-C lighting are a great alternative. All food manufacturers and distributors struggle with keeping pathogens at bay and muddle through bacterial outbreaks, which cause significant loss to these food and beverage manufacturers. Take the peanut butter Salmonella outbreak of 2009, which started in their processing plant- that company, PCA, is now bankrupt. Stave off these bacteria with UV-C technology.

A Note on Using UV Light for Organic Food:

UV-C light can be used on organic foods in most states unlike chemical disinfectants, which is great as organic food demand skyrockets. It's seen an even bigger increase due to COVID-19 too. Organic food cannot legally be irradiated, so UV-C lighting provides a sterilization option here too.

Effectiveness

UV-C lighting is proven to reduce or eliminate many food-borne pathogens, but its effectiveness requires the right exposure time and intensity of irradiation appropriate for each product. With our help placing the right products, this isn't an issue.

Safety

UV-C lighting is safe, and much safer than chemical alternatives or alternatives that alter the density and healthfulness of our foods. But don't just take our word. Here are some sources that cite the safety of UV-C for your reference:

UVC Safely Eliminates Bacteria

Is UV Light Safe For Pathogen Reduction In Food Processing?

Ultraviolet Light Can Kill Bacteria in Fruits, Finds Study

Moreover, germicidal UV-C lighting that protects your employees from sickness is safe too. Here's our take on safety FAQs when it comes to UV technology.

Benefits of proper lighting include:

- Lower Maintenance Costs

- Lower Utility Costs

- Better Quality Control

- Improved Safety & Lower Insurance Rates from Improved Safety Ratings

- Less Absenteeism

- Improved Security

- Lower Reject Rates (Less Errors)

- Tax Advantages

- More Sales

- Improved Image

Choosing the right lighting for your space is important. LEDs provide the right solutions and can fulfill most, if not all, lighting requirements for your industrial space.

Facilities still operating under traditional lighting conditions should consider the following issues with conventional lighting and further explore how an LED retrofit can benefit your business:

Maintenance Requirements

Conventional lighting means more maintenance. Many facility managers wait for a handful of their high bay lights to go out in order to save on maintenance costs, but in the meantime, your production floor can become darker.

Switching to LED high bay lighting can dramatically decrease how often your lighting will need to be replaced. For example, by converting conventional 400 watt HID high bay lighting to LED, a typical building with industrial led light fixtures can save up to $5,341 over the course of three years in maintenance costs alone.

Energy Costs

Conventional lighting technologies generally use a gas or other fuel source, which means your energy bill is much higher than it needs to be.

Conventional lighting is also omnidirectional, which means it emits light 360 degrees. This has two negative consequences: (1) housings or fixtures must direct the light where necessary, and (2) a lot of energy is wasted due to unusable light emissions.

Converting to LEDs can save big on utility costs and we'll explain how further below in this article.

Cycling (Turning On/Off)

Individuals working in a multi-use building or warehouse knows the limitations of High Intensity Discharge (HID) lighting: once you turn those lights off, it’s going to be a while before you can get them on and fully functioning again.

LED lighting solutions eliminate this cycling problem (provide higher quality light)

Achieving the best light levels with the lowest possible energy consumption is critical. There are so many benefits of converting to LED lighting throughout your industrial indoor and outdoor spaces. Let's read some LED benefits below:

Energy Efficient

LED lighting uses semiconductors to emit light, which basically means that electrical current causes light. Common wattages for LED high bay fixtures (the most common in an industrial/factory setting) can range from 95-495 watts. If we compare this to a typical HID high bay fixture, that same range is 175-1000 watts.

LED lighting also beats other technologies on efficiency because the emitted light is directed where you want it and not wasted.

Retrofitting your current industrial lighting with an energy efficient LED solution can save you up to 80% in your energy costs. The savings are so significant that you can finance the replacement with the energy cost savings you will experience as a result!

Reduced Maintenance Costs

Consider all of the bulbs in your facility or parking lot, and how difficult many of them are to repair or replace. Consider what a difference it would make if no bulbs needed to be replaced for, say, 15 years!

Some LED bulbs have 4-40x the useful life of conventional lighting, which means big-time savings on replacement costs.

Lighting Performance

Industrial LED lights will typically score better in a head-to-head comparison against most other bulbs when it comes to Color Rendering Index (CRI), Correlated Color Temperature (CCT), and Foot Candles.

- CRI is a measurement of a light’s ability to reveal the actual color of objects as compared to an ideal light source (natural light). In non-technical terms:

- CCT describes the “glow” given off by a bulb - is it warm (reddish), or cold (bluish white)?

- Foot candles compare the amount of light coming from a source and the amount of light hitting the desired surface; basically a measure of efficiency.

Improved Productivity

Industrial LED lighting can improve assembly accuracy and potentially speed up assembly operations. LED lensing systems direct the light to exactly where it needs to be, and not wasted pointing at the ceiling or spreading too thinly across your surfaces

Many industrial operations require very specific illumination to perform tasks safely and efficiently. LED lensing abilities provide targeted light and proper illumination for areas with unique lighting requirements. With the right lighting, employees are more productive and perform visual tasks with less errors.

Improved Safety

LEDs also help improve the safety of your facility. Improving the quality of light can help visibility, alertness, and productivity, thus helping prevent work-related accidents and safety complications.

LED work station lighting can reduce machine/employee related accidents by making hazards more apparent.

The first step is to speak with an LED lighting solutions provider that is manufacturer-neutral. Why this approach as opposed to the company you may have used for the past several years? Unless that company has a focus on providing LED solutions, it is unlikely that they will have the performance-focused mentality that is required to obtain the desired results of an LED lighting project for your unique (and often regulated) location lighting applications.

A crucial step in any LED project is understanding that LED lighting is NOT a commodity.

Prior decades consisted of building facility managers and building owners evaluating product options purely on cost, assuming that all of the options in consideration were equal in quality - this is not case with LED lighting.

A solution-focused supplier should ask you about your project objectives.

Do you have...

- Budget constraints?

- Return On Investment Criteria?

- Energy reduction targets?

- Lighting performance requirements?

The appropriate partner will want to get an understanding of your desired outcome, not just what specific products they can sell you. Not all LED products are created equal. There are different levels of value from different manufacturers for different applications, and by working with a company that has the product expertise to recommend a solution that meets your project priorities, you will ultimately achieve the best results. We'd love to know more about your upcoming lighting project, contact us and we'll get in touch with you.

-1-1.png?width=400&name=Long%20Industrial%20PP%20Images%20with%20Shadow%20-%20USED%20May%202021%20(1)-1-1.png)

.png?width=700&name=Copy%20of%20Copy%20of%20IP%20CHART%202021%20Stouch%20(1).png)

.png?width=750&name=NSF%20Chart%20Used%20May%202021%20(2).png)

.png?width=400&name=Industrial%20Lighting%20Pillar%20Page%20Block%20Images%20with%20Shadowd%20-%20USED%20May%202021%20(2).png)